Gear pumps for extruder

Gear pumps for extruder include CE, ZB-B, ZB-C, ZB-E, ZB-H, and other series of

extrder gear pump. These melt pumps include high temperature gear pump, high pressure gear pump, standard pumps, etc.

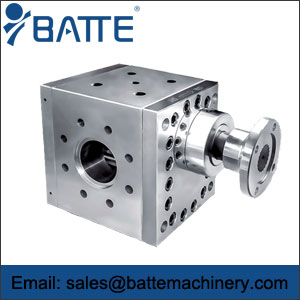

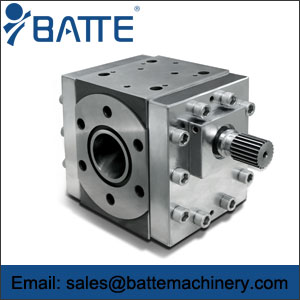

ZB-B and ZB-C series extrusion melt pump details:

ZB-B extrusion melt pump ZB-C extrusion gear pump

ZB-B Series Standard Melt Pump:

ZB-B series standard melt pump is mainly used for extruder or pressurization, stabilizing flow and transportation of medium or high viscosity polymer. This series of melt pump adopts electrical heating, and applies to PS, PP, PET, PVC, PC, PMMA, PA, ABS, PE-LLD, etc.

ZB-B Series Standard Melt Pump Technical Parameter:

Material for Melt Pump Body: High temperature tool steel or chrome-nickel steel

Material for Gear: High temperature tool steel or nitrided steel

Material for Sliding Bearing: High temperature tool steel

Shaft Sealing: Spiral sealing or packing sealing spiral and packing sealing or other combined sealing;

Heating System: Electrical rod heating

Model/Volume Range: 0.5CC - 2500CC, 0.5cm3/rev - 2500cm3/rev

ZB-B Series Standard Melt Pump Operating Parameter:

Viscosity: ≤40000 Pa.s

Working Temperature: ≤400℃ (750℉)

Cleaning Temperature: ≤450℃ (850℉)

Inlet Pressure: ≤12Mpa

Outlet Pressure: ≤40Mpa (6,000psi)

Differential Pressure: ≤25Mpa

|

Type

|

CC/Rev

|

Capacity (L/H)

|

Heating power (kw)

|

Driven system (km)

|

|

ZB-0.2

|

0.2

|

0.1-0.6

|

0.5

|

0.37

|

|

ZB-1

|

1

|

0.5-3

|

1

|

0.5

|

|

ZB-2

|

2

|

1-6

|

1

|

0.75

|

|

ZB-5

|

5

|

2.5-15

|

1

|

1.1

|

|

ZB-10

|

10

|

5-30

|

1

|

1.5

|

|

ZB-20

|

20

|

10-60

|

2

|

2.2

|

|

ZB-31.5

|

31.5

|

15-90

|

2

|

3

|

|

ZB-50

|

50

|

25-150

|

3

|

4

|

|

ZB-100

|

100

|

50-300

|

4

|

5.5

|

|

ZB-150

|

150

|

75-450

|

5

|

7.5

|

|

ZB-200

|

200

|

100-600

|

6

|

11

|

|

ZB-250

|

250

|

125-750

|

8

|

15

|

|

ZB-315

|

315

|

150-900

|

8

|

18.5

|

|

ZB-500

|

500

|

250-1500

|

12

|

22

|

|

ZB-800

|

800

|

400-2400

|

15

|

30

|

|

ZB-1200

|

1200

|

600-3600

|

20

|

37

|

|

ZB-2500

|

2500

|

1300-7500

|

24

|

45

|

|

ZB-3200

|

3200

|

1600-9600

|

24

|

55

|

|

ZB-6200

|

6200

|

3000-18000

|

30

|

75

|

ZB-C Series Reinforced Melt Pump:

ZB-C series reinforced melt pump is mainly used for stabilizing, pressurization and transportation of medium or high viscosity medium from the polymer flow layer. This series of melt pump adopts electrical heating, and applies to PS, PP, PET, PVC, PC, PMMA, PA, etc.

ZB-C Series Reinforced Melt Pump Technical Parameter:

Material for Melt Pump Body: High temperature tool steel, chromenickel steel, titanium tantalum alloy or stainless steel

Material for Gear: M2 Steel (Optional), high temperature tool steel, nitrided steel, or stainless steel, special materials or abrasion-resistant coating

Gear Tooth Type: straight gear, helical gear, herringbone gear

Material for Sliding Bearing: High temperature tool steel, wolfram carbide, stainless steel, special materials or abrasion-resistant coating

Shaft Sealing: (double) spiral sealing

Heating System: Electrical Heating

Model/Volume Range: 0.5CC - 3200CC, 0.5cm3/rev - 3200cm3/rev

ZB-C Series Reinforced Melt Pump Operating Parameter:

Viscosity: ≤40000 Pa.s

Working Temperature: ≤400℃ (750℉)

Cleaning Temperature: ≤450℃ (850℉)

Outlet Pressure: ≤40Mpa (6,000psi)

Inlet Pressure: ≤12MPa

Differential Pressure: ≤25Mpa

|

Pump Model

|

Pump Volume (CC)

|

Driven Power (kw)

|

Heating Power (kw)

|

Working Temperature

|

Working Pressure

|

|

ZB-0.6

|

0.6

|

0.37

|

0.5

|

≤400℃(750°F)

|

Outlet Pressure: ≤ 40Mpa(6,000psi)

Outlet Differential Pressure: ≤ 275Mpa

|

|

ZB-1.2

|

1.2

|

0.75

|

0.5

|

|

ZB-2

|

2

|

0.75

|

1

|

|

ZB-5

|

5

|

1.1

|

2

|

|

ZB-10

|

10

|

1.5

|

2

|

|

ZB-20

|

20

|

2.2

|

2

|

|

ZB-31.5

|

32

|

3

|

2

|

|

ZB-50

|

50

|

4

|

3

|

|

ZB-100

|

100

|

5.5

|

4

|

|

ZB-150

|

150

|

7.5

|

5

|

|

ZB-90/90

|

200

|

11

|

6

|

|

ZB-100/100

|

250

|

15

|

8

|

|

ZB-100/100

|

315

|

18.5

|

8

|

|

ZB-115/115

|

500

|

22

|

12

|

|

ZB-130/130

|

800

|

30

|

15

|

|

ZB-160/160

|

1200

|

37

|

20

|

|

ZB-180/160

|

2500

|

45

|

24

|

|

ZB-180/180

|

3200

|

55

|

24

|

|

ZB-224/224

|

6000

|

75

|

30

|

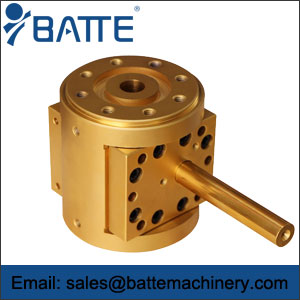

ZB-E series extruder gear pumps:

ZB-E Series Circular Melt Pump:

ZB-E series circular melt pump is mainly used for extruder or pressurization, stabilizing flow and transportation of medium or high viscosity polymer. This series of melt pump primarily adopts electrical heating, and applies to PS, PET, PVC, PC, PA, PMMA, HDPE, LDPE, LLDPE, PP, etc.

ZB-E Series Circular Melt Pump Technical Parameter:

Material for Melt Pump Body: High Temperature Tool Steel

Material for Gear: High Temperature Tool Steel or Nitrided Steel

Material for Sliding Bearing: High Temperature Tool Steel

Shaft Sealing: Spiral Sealing or Packing Sealing

Heating System: Electrical Heating

Model/Volume Range: 0.5CC - 2500CC, 0.5cm3/rev - 2500cm3/rev

ZB-E Series Circular Melt Pump Operating Parameter:

Viscosity: ≤40000 Pa.s

Working Temperature: ≤400℃ (750℉)

Cleaning Temperature: ≤450℃ (850℉)

Inlet Pressure: ≤12MPa

Outlet Pressure: ≤40Mpa (6,000psi)

Differential Pressure: ≤25MPa

|

Type

|

CC/Rev

|

Capacity (L/H)

|

Heating power (kw)

|

Dirven system (km)

|

|

ZB-0.2

|

0.2

|

0.1-0.6

|

0.5

|

0.37

|

|

ZB-1

|

1

|

0.5-3

|

1

|

0.5

|

|

ZB-2

|

2

|

1-6

|

1

|

0.75

|

|

ZB-5

|

5

|

2.5-15

|

1

|

1.1

|

|

ZB-10

|

10

|

5-30

|

1

|

1.5

|

|

ZB-20

|

20

|

10-60

|

2

|

2.2

|

|

ZB-31.5

|

31.5

|

15-90

|

2

|

3

|

|

ZB-50

|

50

|

25-150

|

3

|

4

|

|

ZB-100

|

100

|

50-300

|

4

|

5.5

|

|

ZB-150

|

150

|

75-450

|

5

|

7.5

|

|

ZB-200

|

200

|

100-600

|

6

|

11

|

|

ZB-250

|

250

|

125-750

|

8

|

15

|

|

ZB-315

|

315

|

150-900

|

8

|

18.5

|

|

ZB-500

|

500

|

250-1500

|

12

|

22

|

|

ZB-800

|

800

|

400-2400

|

15

|

30

|

|

ZB-1200

|

1200

|

600-3600

|

20

|

37

|

|

ZB-2500

|

2500

|

1300-7500

|

24

|

45

|

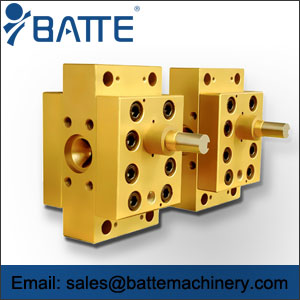

ZB-H series extrusion melt pump:

ZB-H Series High Temperature & High Pressure Melt Pump:

ZB-H series high temperature & high pressure melt pump are applicable for engineering plastic or blown film technique.

ZB-H Series High Temperature & High Pressure Melt Pump Technical Parameter:

Material for Melt Pump Body: CPM Tool Steel or Titanium Tantalum Alloy

Material for Gear: CPM tool steel, titanium tantalum alloy, special materials or abrasion resistant coating

Material for Sliding Bearing: CPM tool steel, titanium tantalum alloy, special materials or abrasion resistant coating

Shaft Sealing: Spiral Sealing

Heating System: Electrical Heating

Model/Flow Range: 5CC - 2500CC, 5cm3/rev - 2500cm3/rev

ZB-H Series High Temperature & High Pressure Melt Pump Operating Parameter:

Viscosity: ≤20000 Pa.s

Working Temperature: ≤510℃ (950℉)

Cleaning Temperature: ≤590℃ (1100℉)

Inlet Pressure: ≤20MPa

Outlet Pressure: ≤70MPa

Differential Pressure: ≤50MPa

|

Pump Model

|

Pump Volume (CC)

|

Capacity (L/H)

|

Driven Power (kw)

|

Heating Power (kw)

|

Working Temperature

|

Working Pressure

|

|

ZB-0.1

|

0.1

|

0.05-0.2

|

0.2

|

1

|

≤400℃(750°F)

|

Outlet Pressure: ≤ 350Mpa

Outlet Differential Pressure: ≤ 275bar

|

|

ZB-0.5

|

0.5

|

0.25-1

|

0.37

|

1

|

|

ZB-1

|

1

|

0.5-2

|

0.55

|

1

|

|

ZB-2

|

2

|

1-4

|

0.75

|

1

|

|

ZB-5

|

5

|

2.5-10

|

1.1

|

2

|

|

ZB-10

|

10

|

5-20

|

1.5

|

2

|

|

ZB-20

|

20

|

10-40

|

2.2

|

2

|

|

ZB-31.5

|

32

|

16-60

|

3

|

2

|

|

ZB-50

|

50

|

25-100

|

4

|

3

|

|

ZB-100

|

100

|

50-200

|

5.5

|

4

|

|

ZB-150

|

150

|

75-300

|

7.5

|

5

|

|

ZB-90/90

|

200

|

100-400

|

11

|

6

|

|

ZB-100/100

|

250

|

125-500

|

15

|

8

|

|

ZB-100/100

|

315

|

150-300

|

18.5

|

8

|

|

ZB-115/115

|

500

|

200-1000

|

22

|

12

|

|

ZB-130/130

|

800

|

400-1600

|

30

|

15

|

|

ZB-160/160

|

1200

|

600-2400

|

37

|

20

|

|

ZB-180/160

|

2500

|

1250-5000

|

55

|

20

|

|

ZB-180/180

|

3200

|

1600-6400

|

55

|

24

|

|

ZB-224/224

|

6000

|

3000-6000

|

75

|

30

|

Relative Articles:

◆ZB-F gear pump for reaction kettle

◆ZB-K gear pump for reactor

◆Chemical metering gear pumps

◆ZB-D pipeline gear pump

◆ZB-R rubber gear pump

◆RS double shaft rubber pump

◆ZB-U gear metering spinning pump