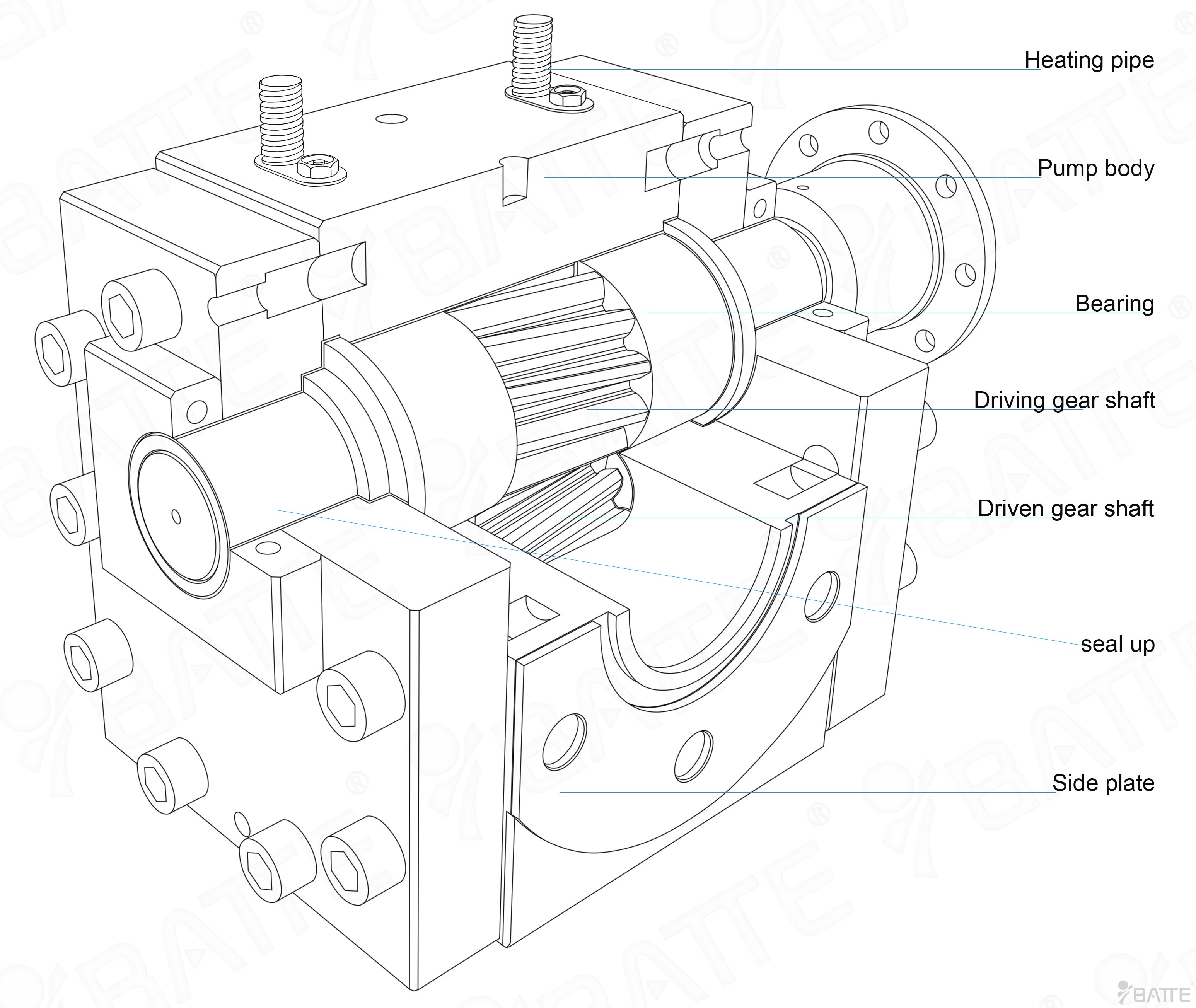

Composition of High Temperature and High Viscosity Melt Gear Pump

High temperature and high viscosity melt gear pump is mainly composed of pump body, front and rear side plates, two meshing gears, bearings and seals; The space formed by the tooth profiles of two gears, the pump body and the side plate constitutes the feeding area, the conveying area and the discharging area of the pump. Gear is the core part of high temperature melt extrusion gear pump, and its structural forms are various; According to the meshing mode, it can be divided into internal and external meshing modes; According to the tooth profile curve, it can be divided into involute gear, circular arc gear, cycloidal gear, etc; It can be divided into spur gear, helical gear and herringbone gear according to tooth direction, but involute spur gear and helical gear are commonly used in conveying plastic melt.

Compared with other types of gear pumps, the gear pump for high temperature and high viscosity melt has the advantages of compact structure, reliable operation, low energy consumption, high volumetric efficiency, small shearing effect on the melt, stable flow when conveying high viscosity and high pressure, and no outlet pressure fluctuation. The unique advantages of the pump and its key role in the process flow make it play an irreplaceable role in polyester production.

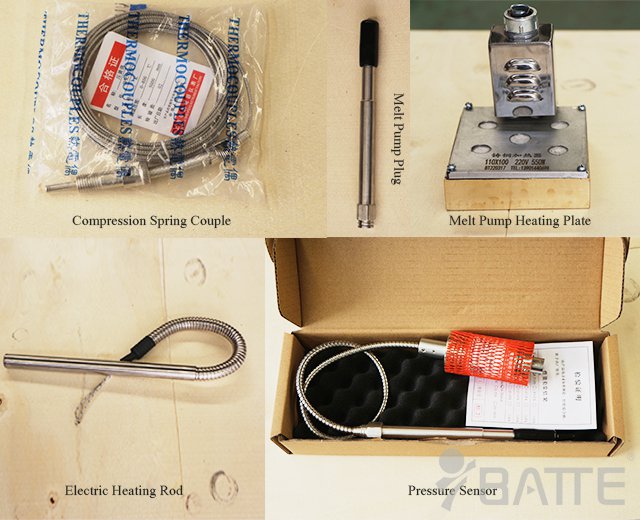

Zhengzhou Batte melt pump manufacturers can provide high wear resistance, corrosion resistance and some special material configurations according to different working conditions of customers. At the same time, it can also provide electric heating rod, electric heating plate, junction box, thermal resistance, pressure sensor and other accessories as well as a complete set of solutions such as polypropylene melt pump drive device, base, control system and screen changer. info@battemachinery.com