The importance of selecting the stainless steel gear pump

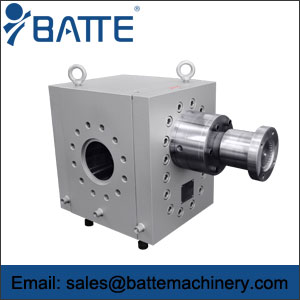

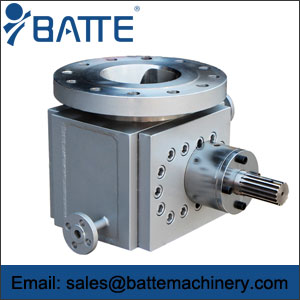

Stainless steel gear pumps are mainly composed of 5 parts, namely, gear, shaft, pump body, safety valve and shaft end seal. The gear has high hardness and strength through heat treatment and is installed with the shaft in the replaceable shaft sleeve. The lubrication of all parts in the pump is automatically achieved by using the output medium when the pump works. The pump has a reasonable design of oil drain and oil return tank, which is the smallest torque load in the gear, so the bearing load is small, the wear is small, and the pump efficiency is high.

The key problem for the stainless steel gear pump is the problem of the availability of the gear pump. Generally, the stainless steel gear pump is mainly used in chemical, medical, food and other occasions. The medium is a mixed liquid that does not contain solid materials. The motor and pump are very close to the pump. The pump is arranged in the supine type, and the weight of the rotating parts is connected with the impeller. Water pressure is in the same direction. These problems make the stainless steel gear pump in the sealing, motor bearing capacity, bearing layout and selection and other aspects of the request than the ordinary gear pump to be high. The service life is long, so the market share is increasing.