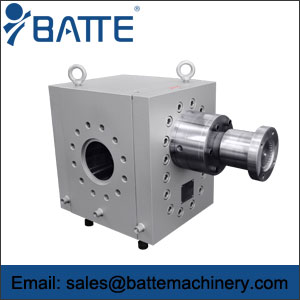

Melt gear pump solution

For conventional extruders, there are usually such problems:

The fluctuation of temperature and pressure of the extrudate caused by improper control of process conditions and pulsation of the motor load affect the quality of the product;

As the extrusion pressure increases, the reverse flow and the leakage flow will inevitably increase, resulting in a decrease in the overall extrusion flow rate. At the same time, the power consumed by the screw to push the material is also large, the shear force on the material is large, and the energy consumption is large;

When the polymer is blended and modified, in order to have a uniform temperature and pressure distribution of the extrudate, it is necessary to increase the length of the metering section, which further increases the aspect ratio of the screw. This not only increases the difficulty and cost of processing, but also increases the residence time of the material, which is not conducive to the processing of heat-sensitive materials; in addition, there is a problem of insufficient extrusion pressure for screw extruders that require direct extrusion of products.

Melt gear pumps can solve these problems well. It separates the melted plasticizing section of the polymer from the metering section and pressurizes, regulates, and delivers the high temperature plastic melt from the extruder precisely and steadily to the extruder head, which can be at 350°C and 35 MPa. Continuous work under high pressure. The gear pump is a positive displacement conveying device. Its outlet pressure is not affected by the change of the inlet pressure, and its volumetric efficiency and energy efficiency are high. It can not only meet the operational stability of the equipment, but also improve the product quality requirements, and can also meet high efficiency. Low energy requirements. In addition, the gear pump has the characteristics of small size, high output, and easy maintenance. It is widely used in high-pressure, high-precision extrusion and compound co-extrusion processing technologies. It can be said that the extruder is equipped with a melt gear pump that is ly crowded. A development feature of processing..